Problem definition:

Many wineries have no precise knowledge of their energy consumption and energy sources used

Only annual consumption is known for energy sources

No knowledge of the energy mix used

Potential energy savings are not recognized or are recognized too late

Use of outdated technology (cooling, lighting, heating)

Decline in efficiency and efficiency of individual machines and energy lines (electricity, cooling/heating) are not known

No precise knowledge of the output of their own PV system (production, own consumption, feed-in, time peaks)

Obsolete machines are often replaced too late because the performance and efficiency of the energy components are not measured.

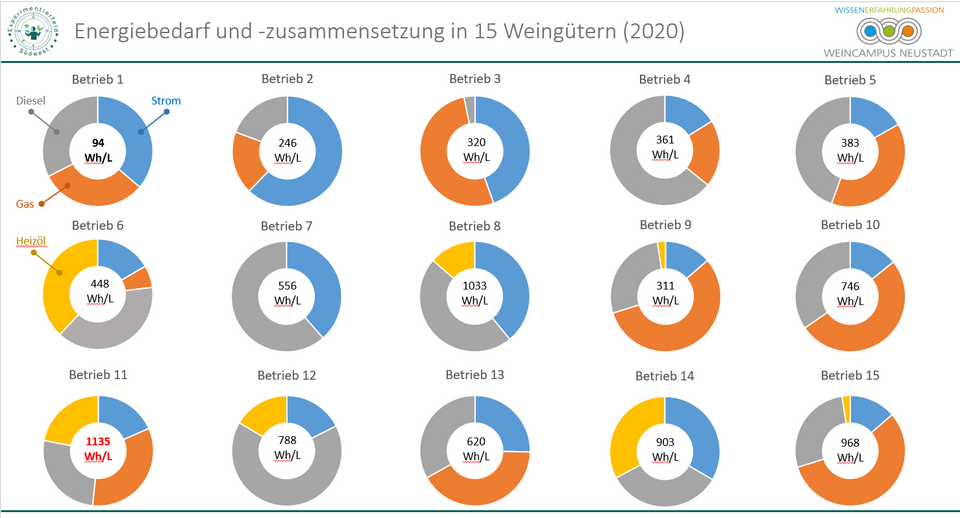

Initial research results show that German wineries use different energy mixes for wine production and that there are large fluctuations in the amount of energy required per liter of wine.

The main energy sources in viticulture are:

Structure of the research project:

Development and integration of an energy management system (EnMS) in small and medium-sized wineries to measure the energy flows of all energy sources used in wine production by

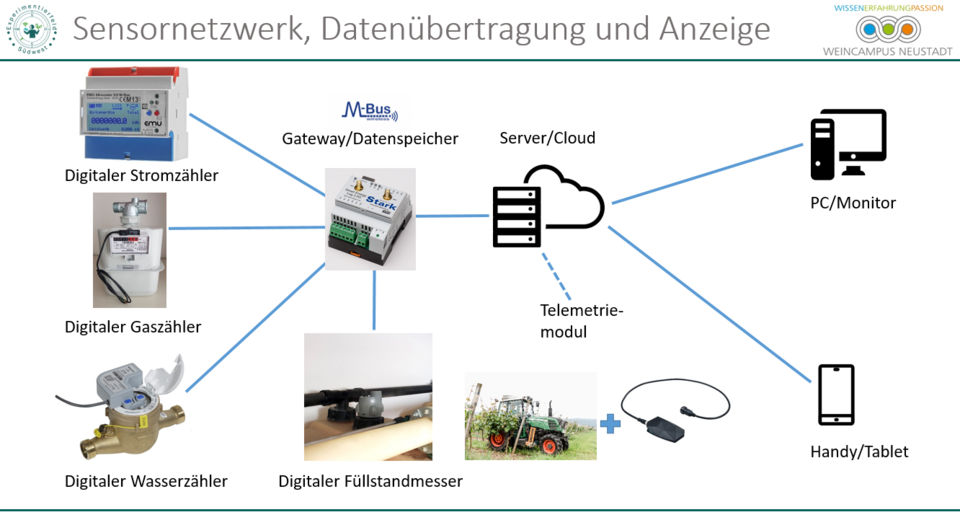

Installation of sensors that accurately record the energy use of different consumers and the various energy sources, broken down by room, work step or individual appliance. The sensors can record all the different energy sources.

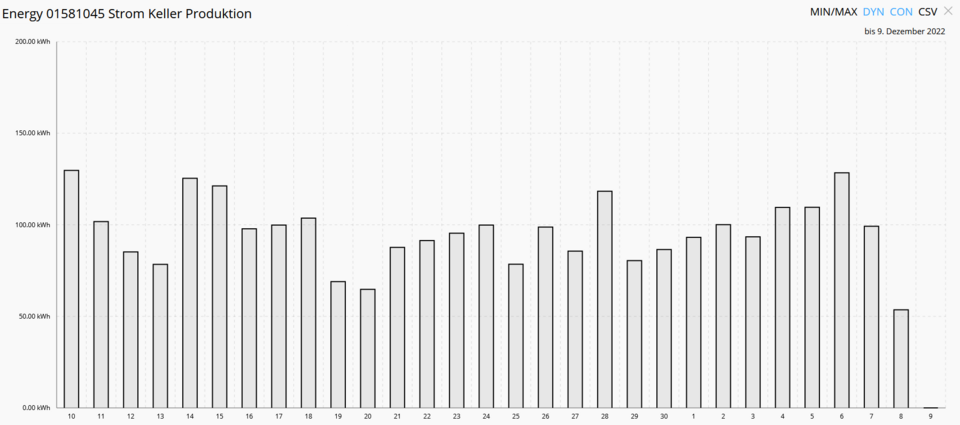

The energy data, which is collected automatically and closely (every 5 minutes) by telemetry, is processed and evaluated using software. Individual load profiles are visualized and can be called up using a computer, tablet or smartphone via the Vinergy app.

The energy data collected from various wineries is stored and analyzed on a central server by the DLR-RP in Neustadt an der Weinstraße. This allows a cross-regional comparison of different types of operation and is used for individual energy consulting by the DLR-RLP.

In this way, winegrowing businesses receive precise values on their internal energy use and can take various steps on the basis of this data, such as

Anonymous comparison with similar types of operation

Energy efficiency assessment

Analysis of the efficiency and function of individual appliances

Checking the applicability and cost-effectiveness of optimization approaches developed as part of the CIP.

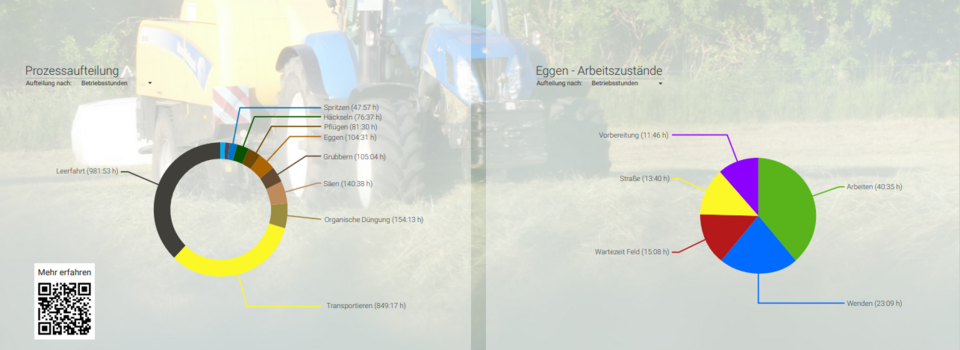

Fuel consumption of vineyard tractors

In contrast to the rest of the agricultural sector, there is no measurement option ex works.

Data is collected directly in the tractor using a computer system and processed automatically.

The following parameters are recorded:

Fuel consumption/hour/minute/ha,

area output ha/h, co2/ha

Distance traveled and time

Work steps and attachments such as leaf cutters or cultivators

Road travel, work, turning, preparation, turning time and distance

It is possible to calculate the costs of the individual tasks in the vineyard

Aims of the research project:

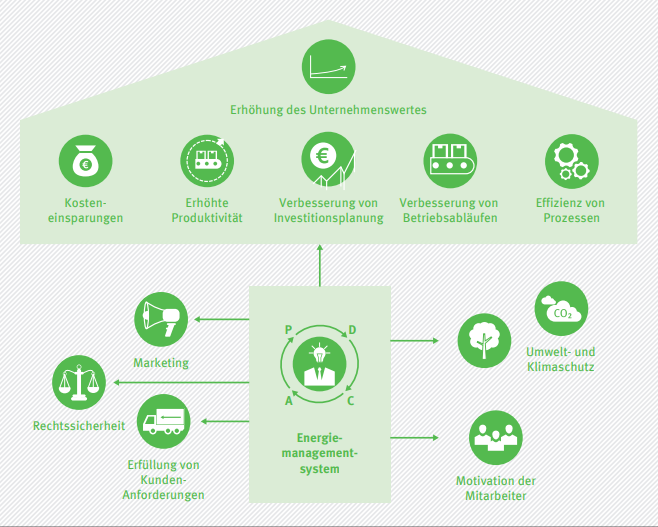

Development of a user-friendly energy management system based on automated energy monitoring.

An EnMS can be used as a basis for certifying your own company in ecological and sustainability issues

Planning the use of resources and making them more efficient

Cost savings

Individual advice for wineries from DLR on energy efficiency and energy savings based on the data collected

Introduction of fixed measurement units

kWh/liter of wine and kWh/ha of vineyard

Raising awareness of energy use/efficiency among employees and customers

Advantages of an integrated energy management system (EnMS)

Fabian Marnet